Design

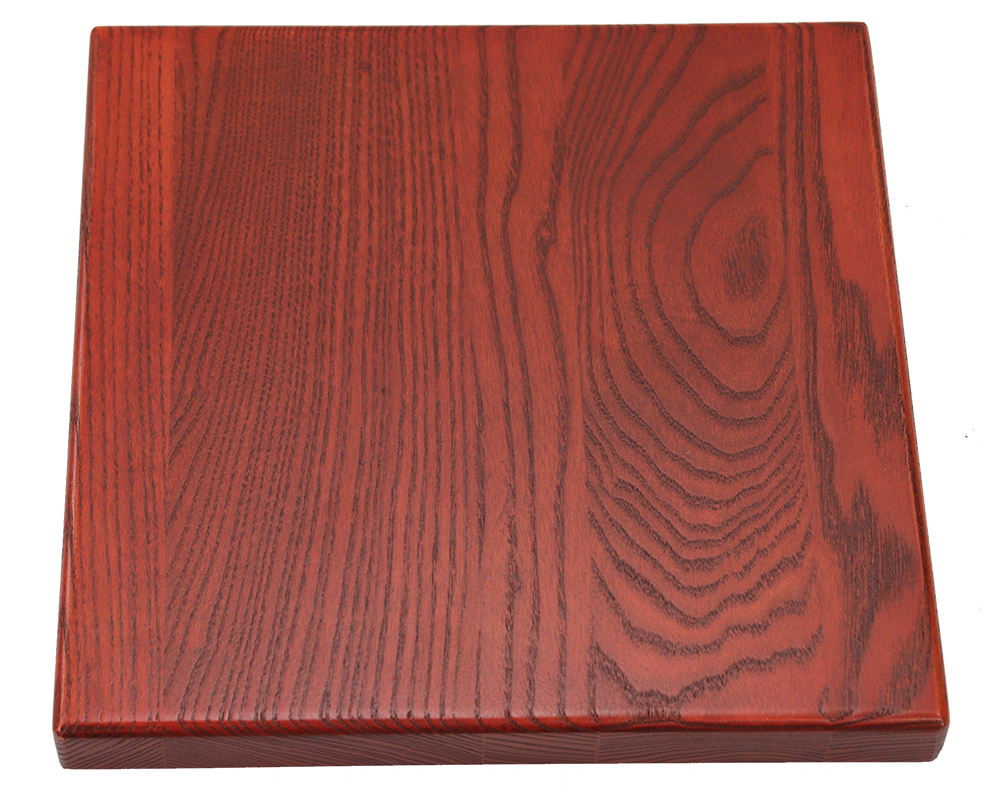

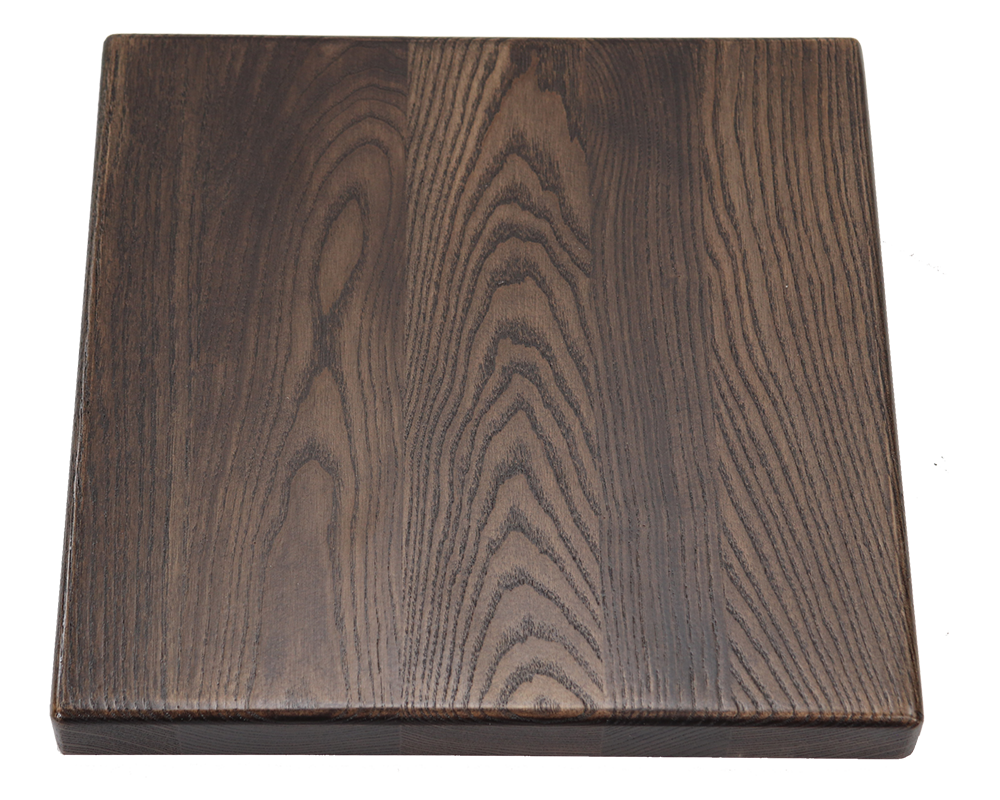

Wood Species

We stock several different species of wood, in several lumber sizes. The most popular wood we stock is Ash, Soft and Hard Maple, Red and White Oak, Cherry, Walnut, and Mahogany.

Table Tops

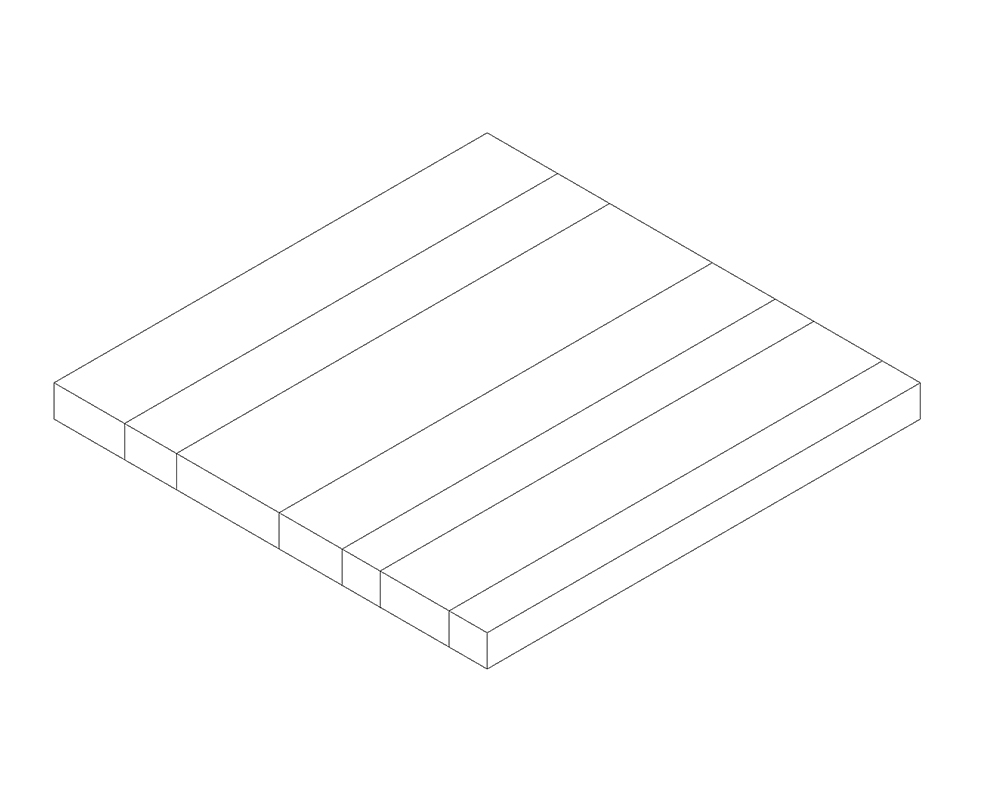

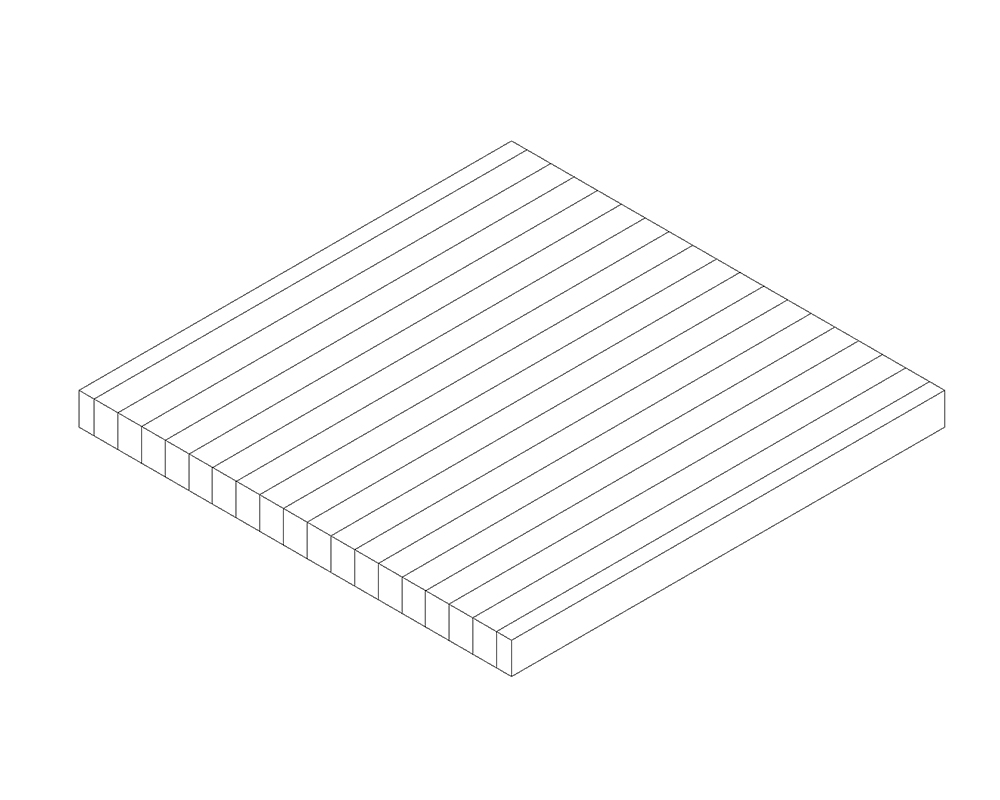

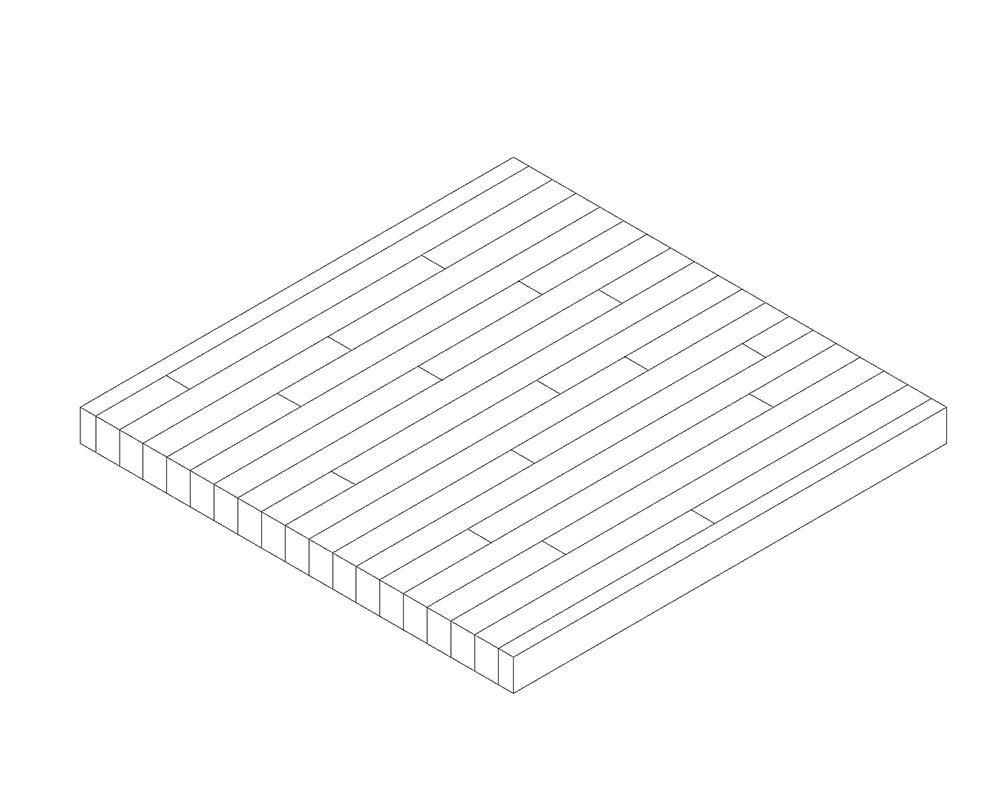

We want to help you understand the terminology used when talking about solid wood table tops. Solid wood tops come in either plank or butcher block form. Plank form refers to the lumber in the raw form that we receive from the sawmills. The face grain will be showing, which gives a more traditional and elegant look. Butcher block refers to the look achieved when we cut the planks into multiple strips of wood, then turn the pieces 90 degrees placing the end grains face-up.

Next to understanding solid wood tops are the terms full length or butt joint. Full length refers to pieces that are cut to the exact length of the top. Butt joint is a term to describe small pieces of wood that are jointed together to form a longer length top. See below for reasons why a customer would need or want to use a butt-jointed top.

Mainly for three reasons:

1) A solid piece of lumber is not available for the desired table length; thus needing to join small pieces together to achieve the target dimension.

2) Using a butt-jointed top creates unique and appealing table tops.

3) The customer is hoping to maintain cost effectiveness (using butt-jointed pieces creates less lumber waste).

For efficiency throughout the entire plant, and not being penalized for a “special size” table top, the table must stay under: 48″ x 96″ (4 feet x 8 feet)

Max sizes for “special” table top orders:

- Max size we can glue up in the clamp: 51″ wide x 156″ long (13 feet)

- Max size we can run through our planer/sander: 63″ wide x 156″ long (13 feet)

- Max size we can run through our polish sander: 75″ wide x 96″ long (8 feet)

Finishes

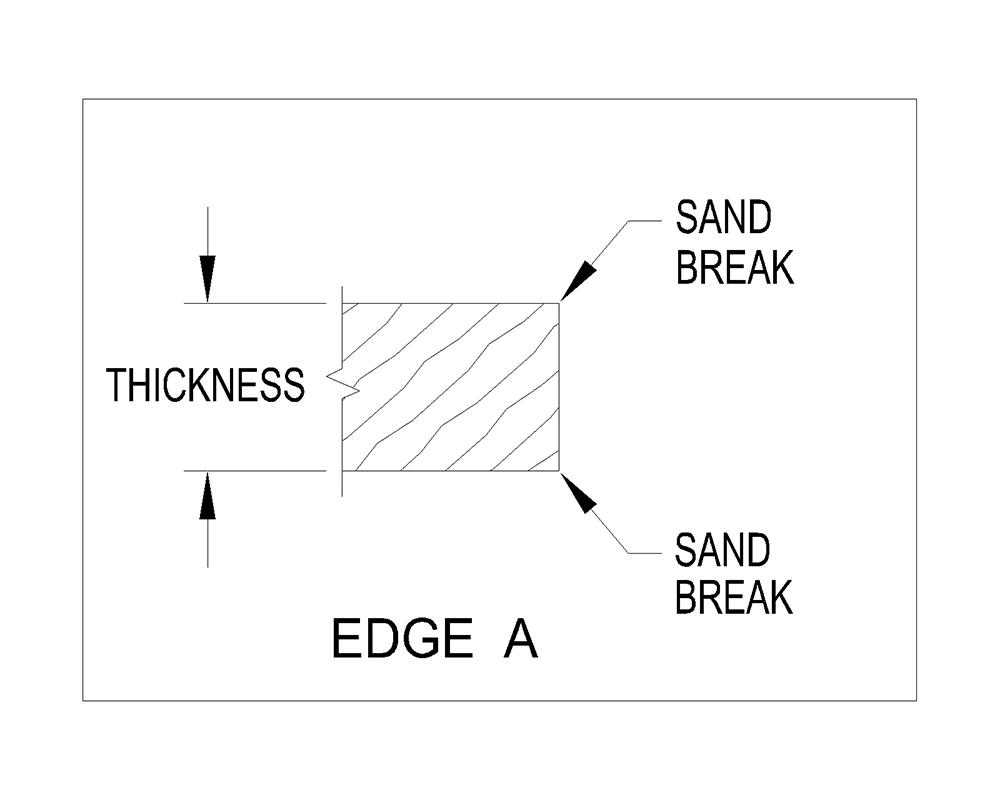

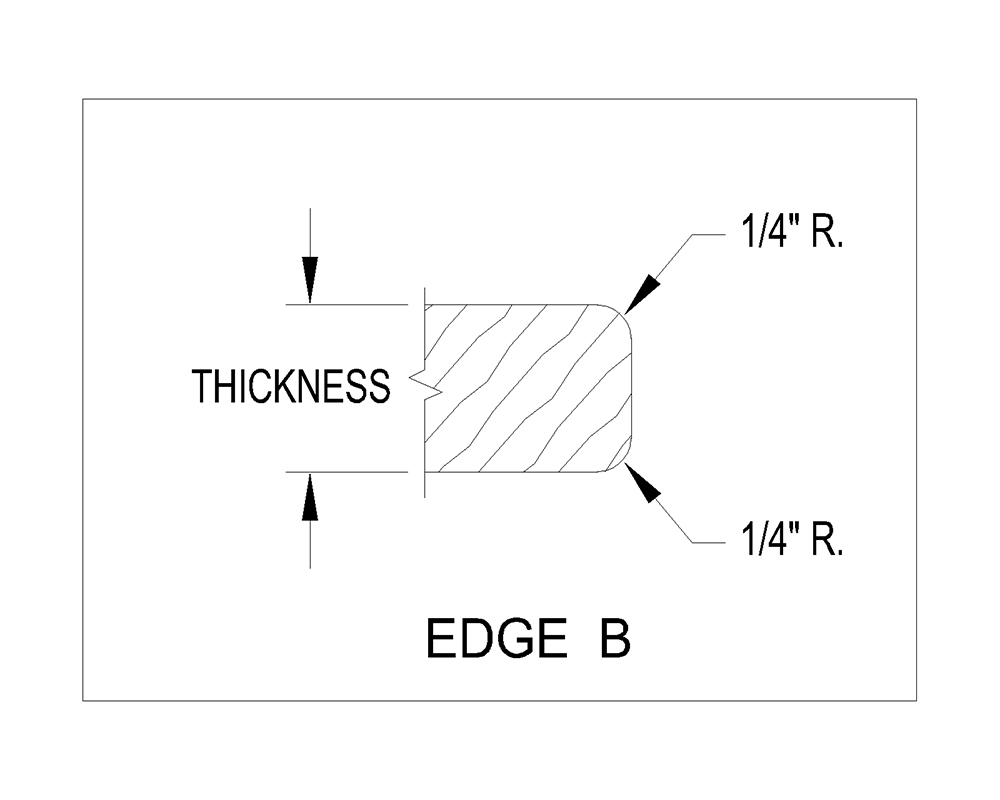

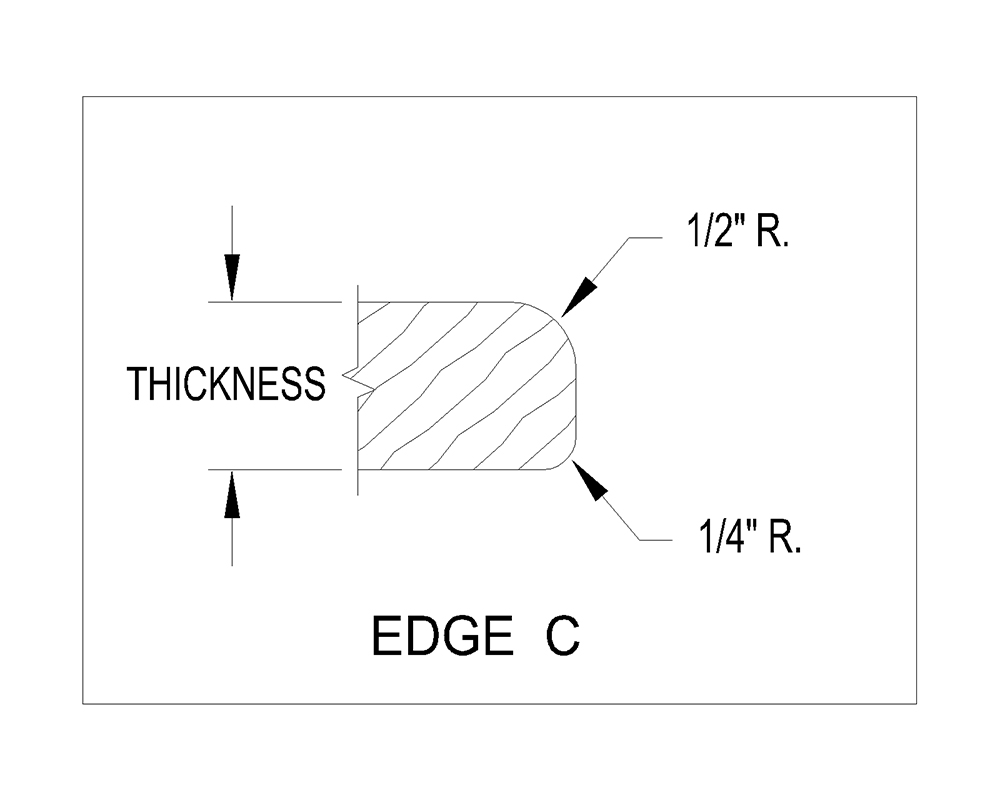

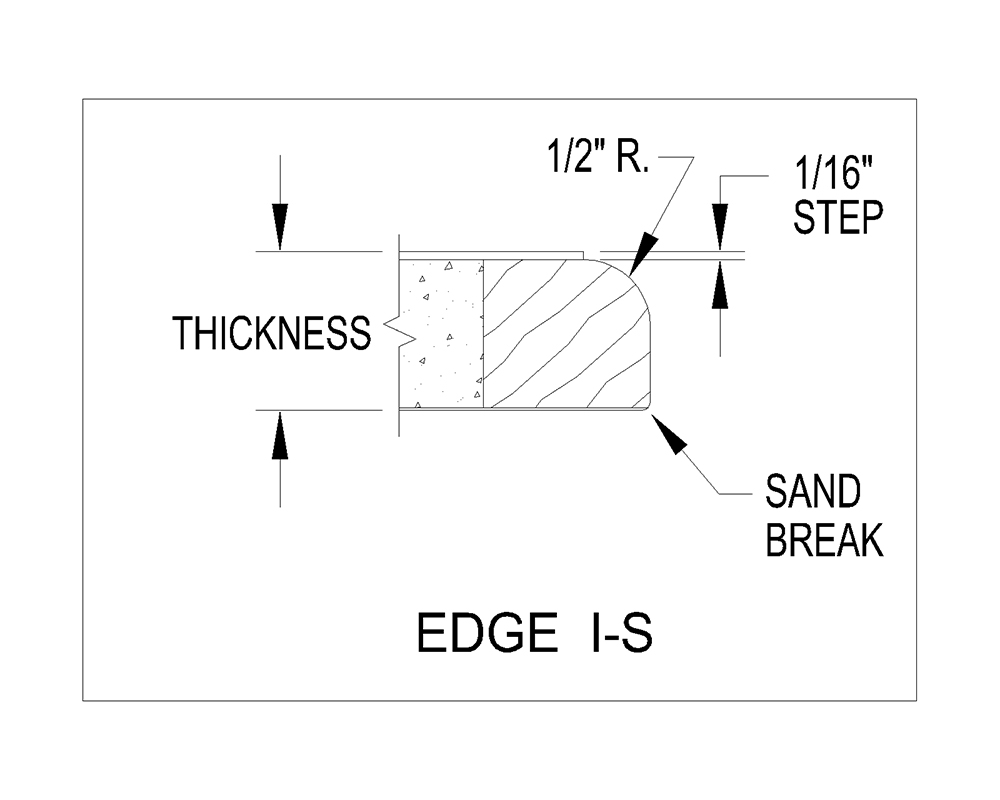

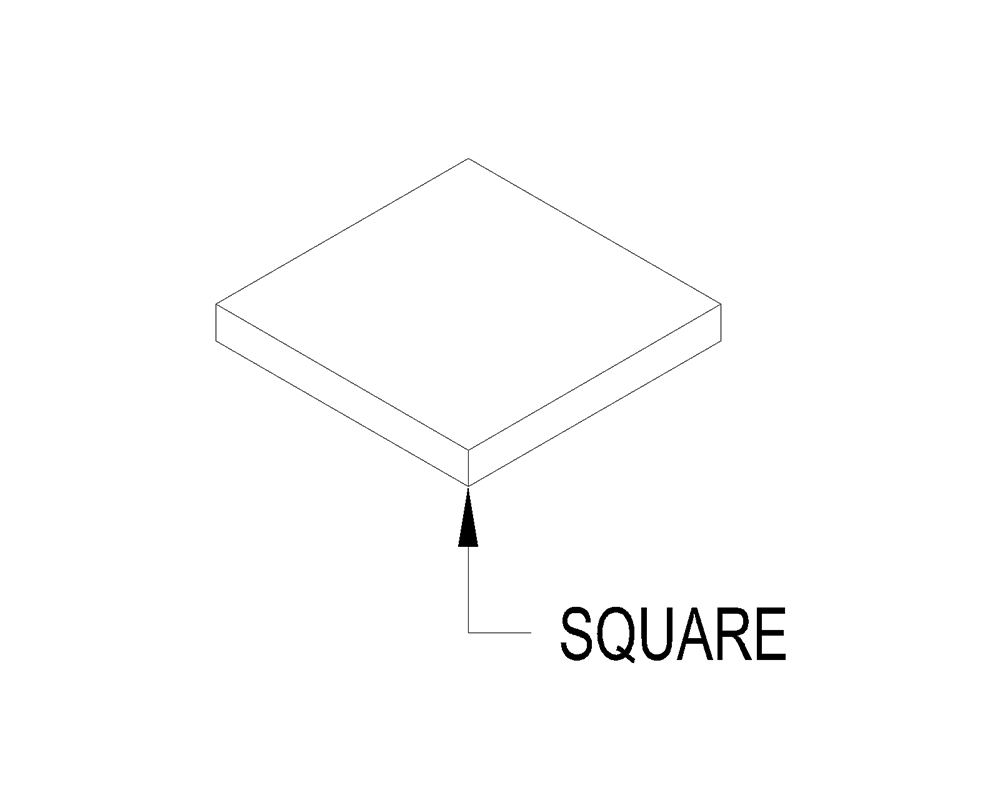

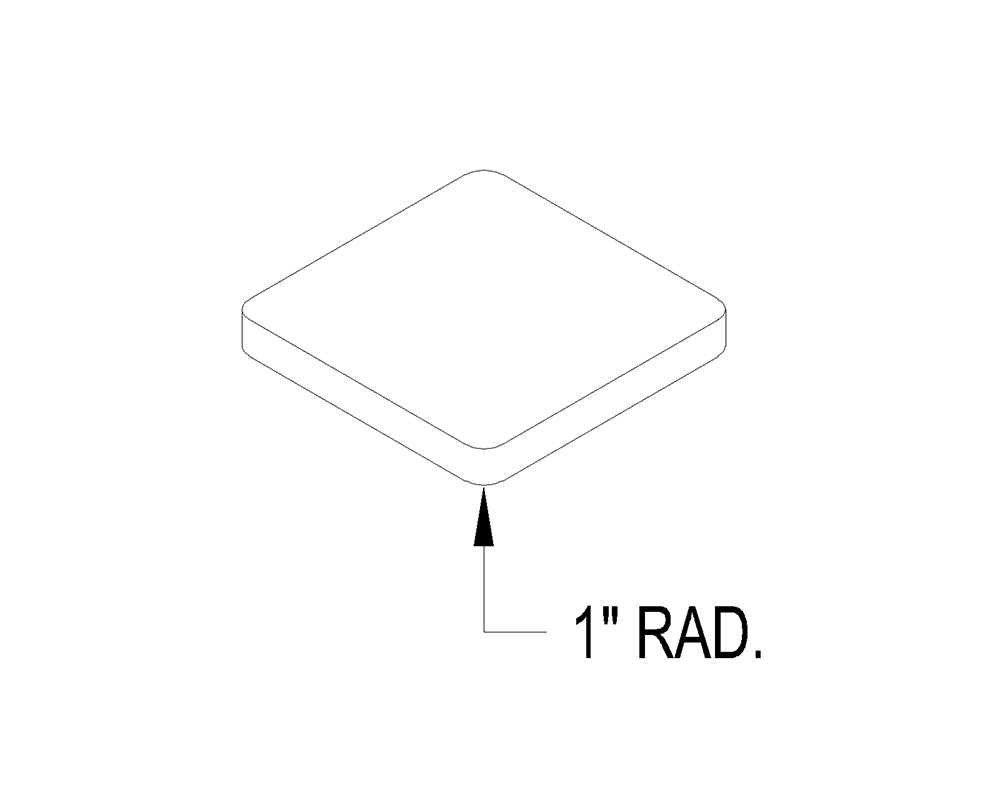

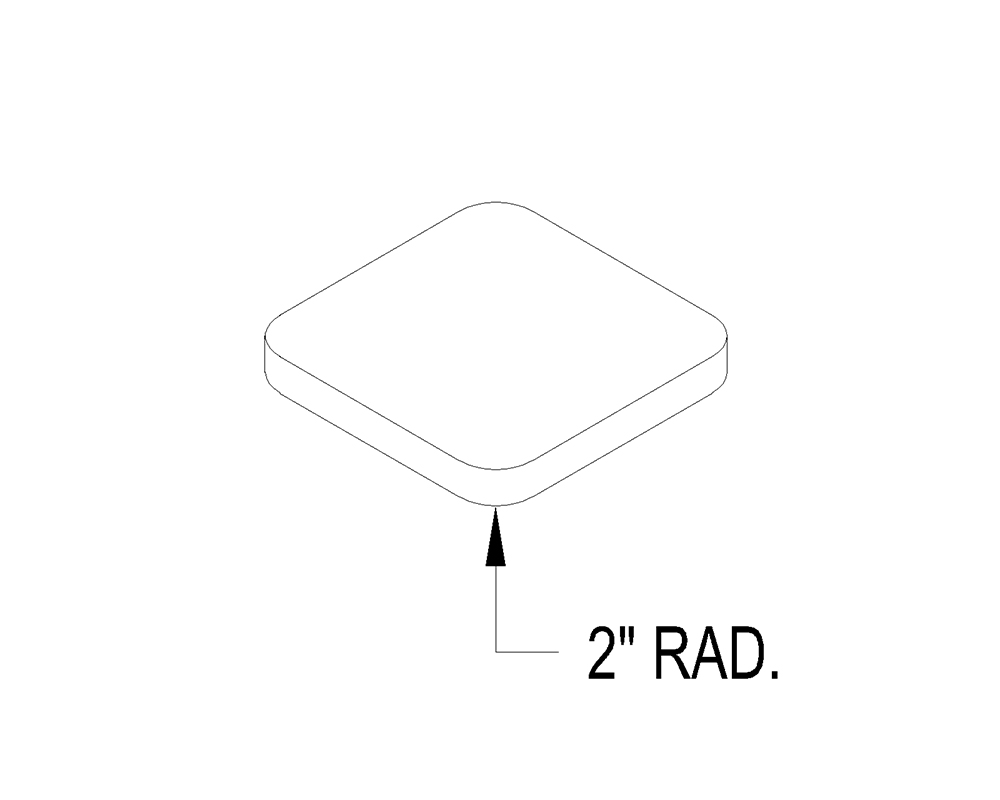

Table Edges

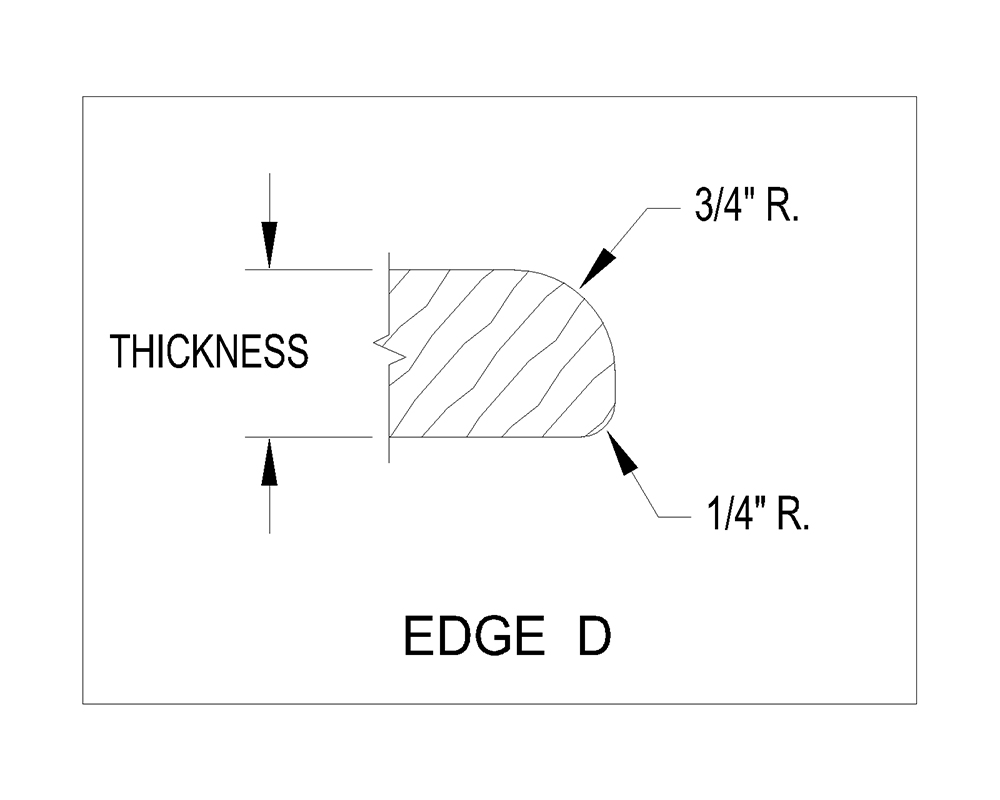

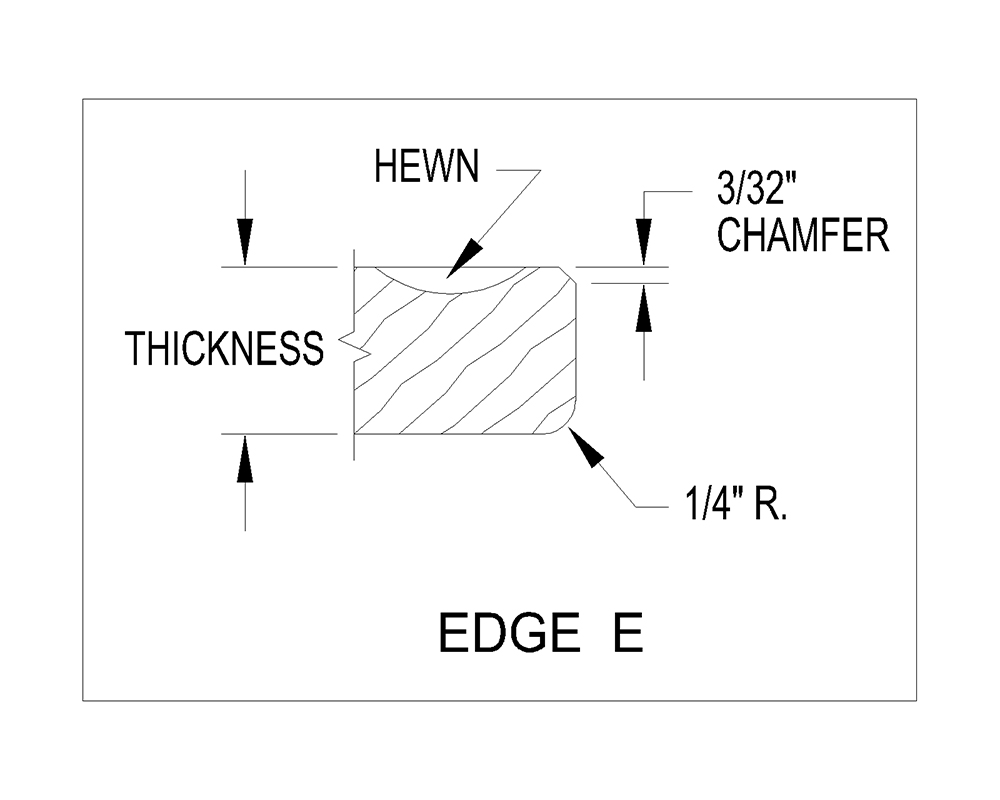

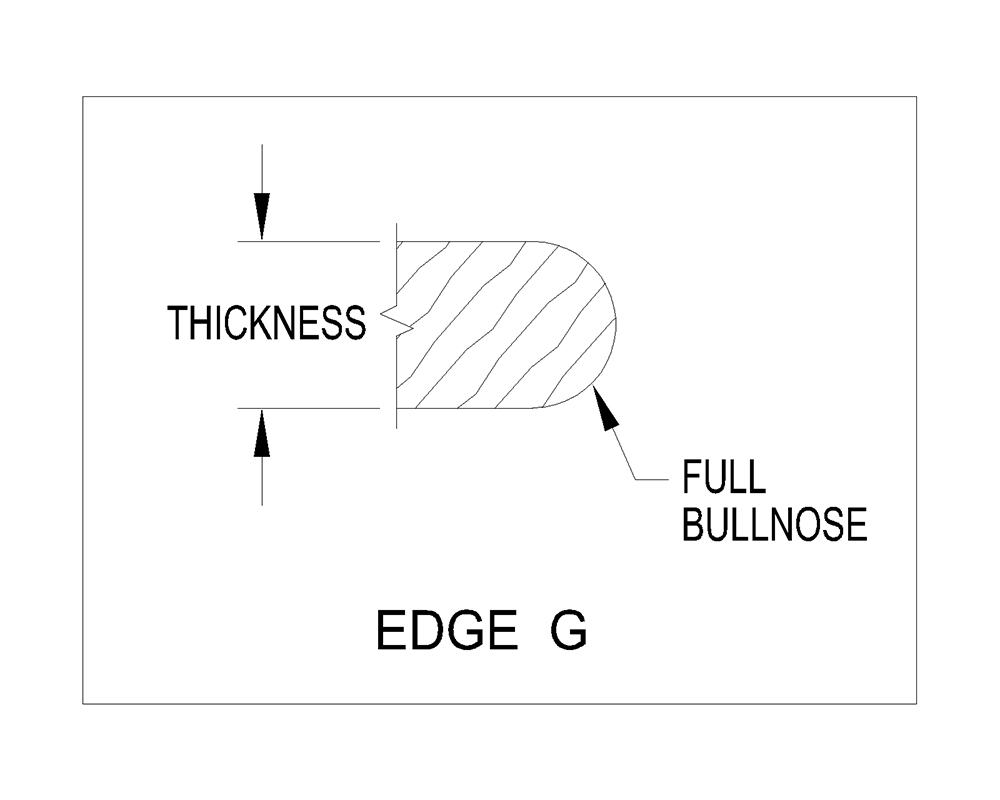

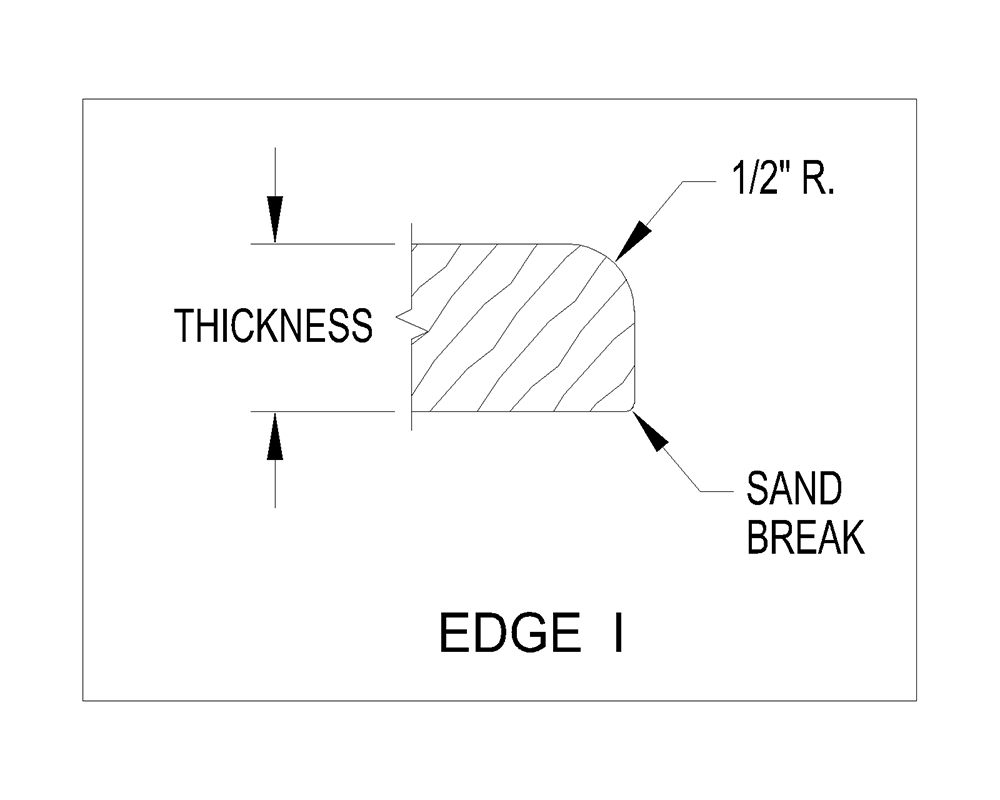

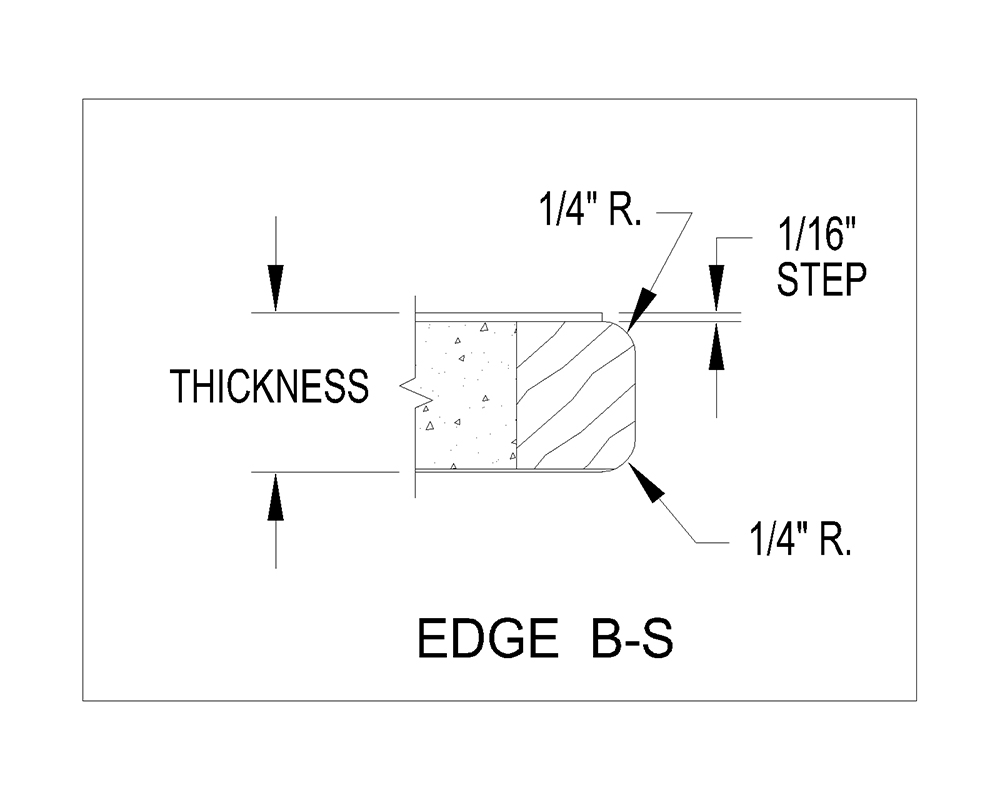

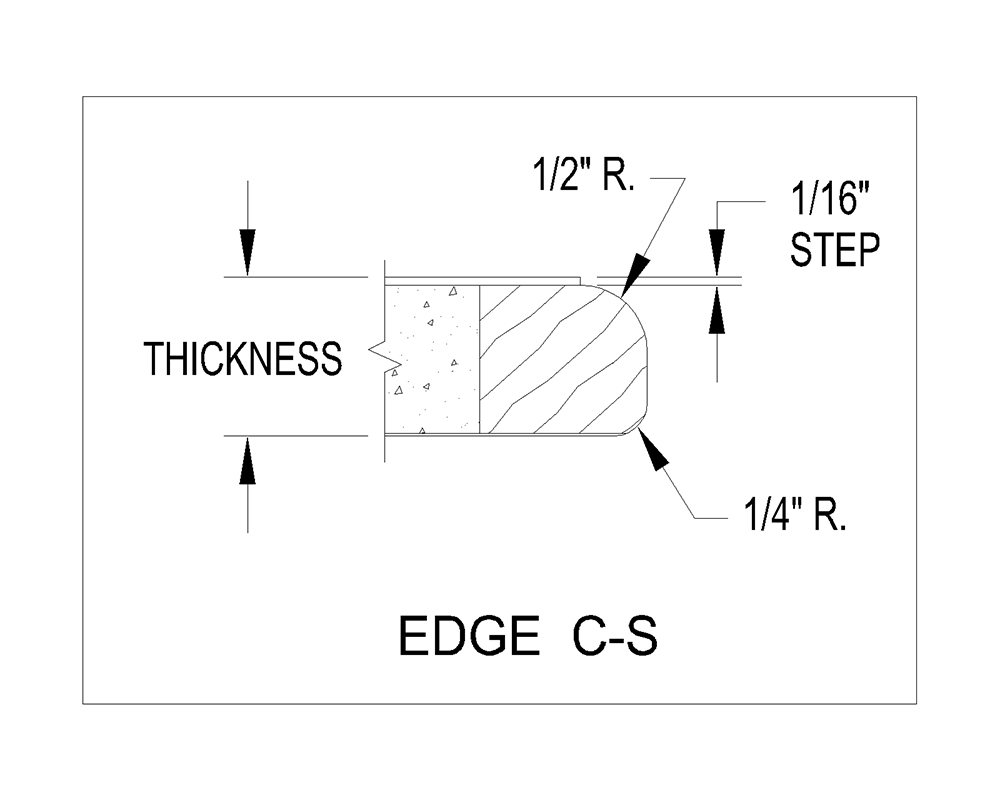

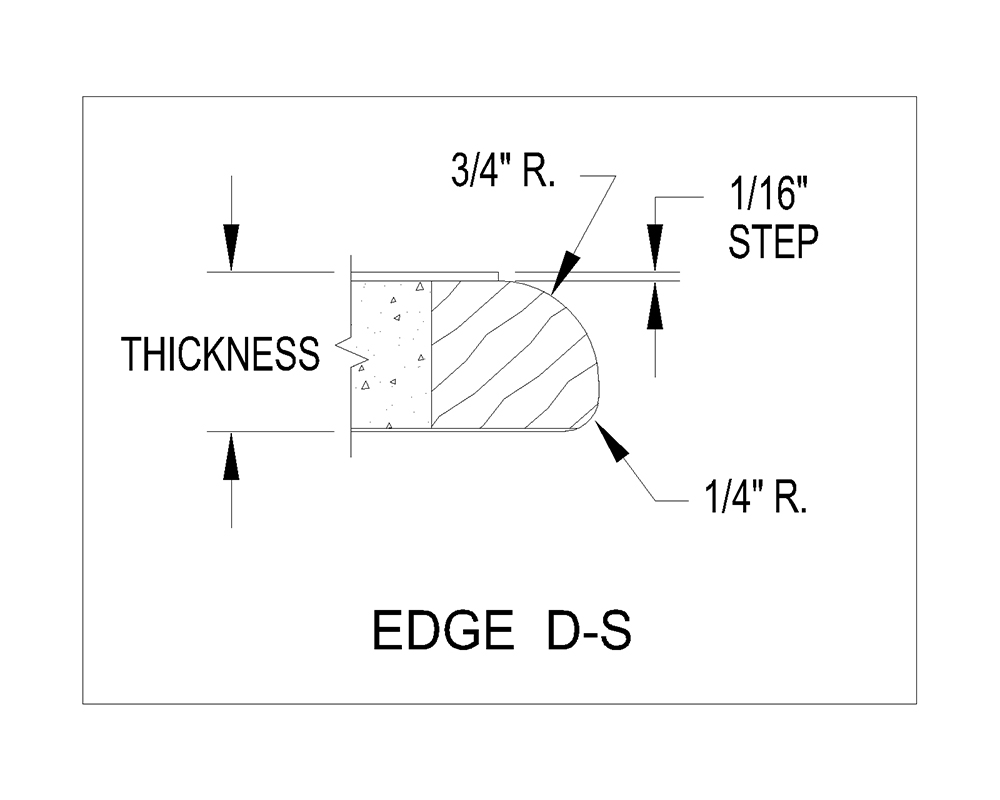

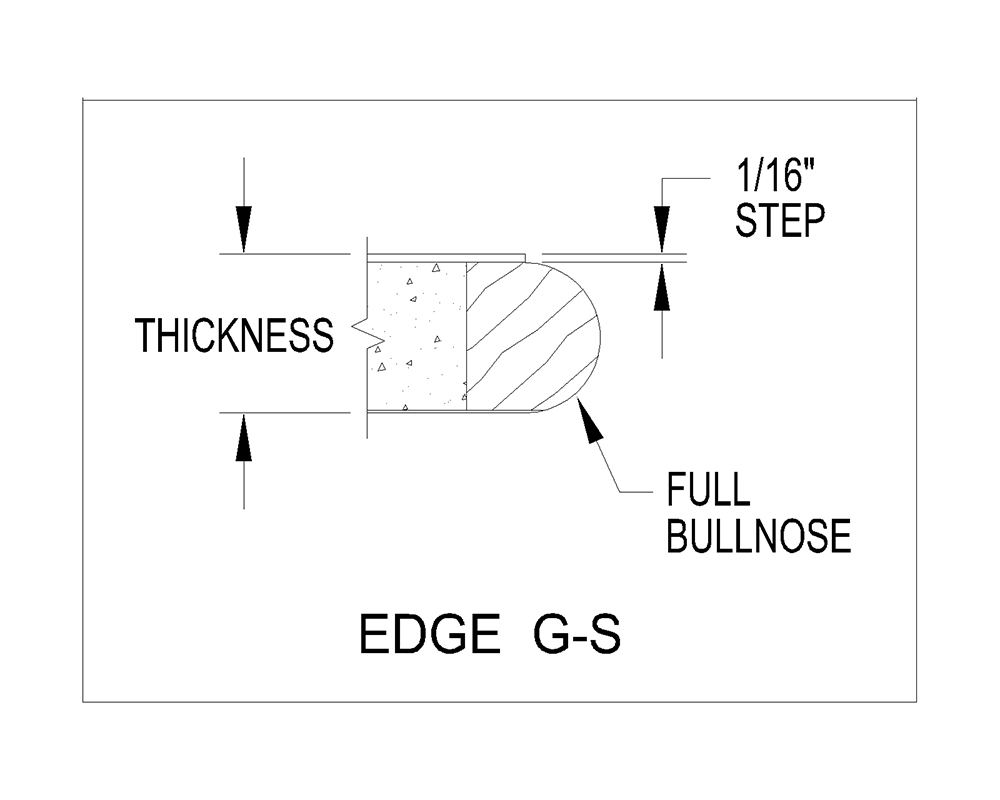

Edges can be overwhelming, because there are so many to choose from. To help narrow the search, we are displaying the ones that 95% of our customers choose. We like to to call them the most popular ones! If you find yourself not liking any of these, we are more than happy to send you more options.

Wood Top Edges

Laminate Edges

Booths

When it comes to booths, asking to change the height or depth of the booth is the more difficult task. It essentially means you are creating a whole new booth, because all the parts change size. Then we have to update all the plant drawings and directions.

Engineering Fee: ~$1,000 (depending on booth)

When it comes to changing the length “width” of the booth, that isn’t as hard to do (not as time consuming). Changing the length “width” only takes a few hours and consists of stretching or shrinking the booth (where most parts stay the same size).

Engineering Fee: ~$200 (depending on booth)